-

Equipment

Back

Equipment

-

New Machines

Back

New Machines

Hydraulic Mining Shovels

Hydraulic Mining Shovels

Underground - Hard Rock

Underground - Hard Rock

Articulated Trucks

Articulated Trucks

Off-Highway Trucks

Off-Highway Trucks

Excavators

Excavators

Dozers

Dozers

Motor Graders

Motor Graders

Wheel Loaders

Wheel Loaders

Road Reclaimers

Road Reclaimers

Compactors

Compactors

Asphalt Pavers

Asphalt Pavers

Cold Planers

Cold Planers

Telehandlers

Telehandlers

Track Loaders

Track Loaders

Pipelayers

Pipelayers

Wheel Tractor-Scrapers

Wheel Tractor-Scrapers

Skid Steer and Compact Track Loaders

Skid Steer and Compact Track Loaders

Electric Rope Shovels

Electric Rope Shovels

Draglines

Draglines

Backhoe Loaders

Backhoe Loaders

Drills

Drills

- Rental

- Used Equipment

- Engines

- CAT Lift Trucks

-

Work Tools

Back

Work Tools

Augers

Augers

Backhoes

Backhoes

Bale Grabs

Bale Grabs

Bale Spears

Bale Spears

Blades

Blades

Brooms

Brooms

Brushcutters

Brushcutters

Buckets - Backhoe Front

Buckets - Backhoe Front

Buckets - Backhoe Rear

Buckets - Backhoe Rear

Buckets - Compact Wheel Loader

Buckets - Compact Wheel Loader

Buckets - Excavator

Buckets - Excavator

Buckets - Loader

Buckets - Loader

Buckets - Mining Shovels

Buckets - Mining Shovels

Buckets - Skid Steer Loader

Buckets - Skid Steer Loader

Buckets - Telehandler

Buckets - Telehandler

Cold Planers

Cold Planers

Compactors

Compactors

Couplers - Loader

Couplers - Loader

Felling Heads

Felling Heads

Flail Mowers

Flail Mowers

Forks

Forks

Generator Set Enclosures

Generator Set Enclosures

Hammers

Hammers

Mulchers

Mulchers

Rakes

Rakes

Rippers

Rippers

Saws

Saws

Silage Defacers

Silage Defacers

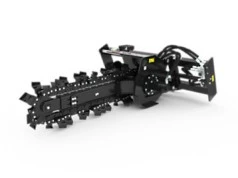

Trenchers

Trenchers

Winches

Winches

Couplers - Excavator

Couplers - Backhoe Rear

Couplers - Excavator

Couplers - Backhoe Rear

- Metso

-

New Machines

- Parts

- Service & Support

- Promotions

-

Technology

Back

Technology

AN ONLINE HUB FOR YOUR EQUIPMENT INFORMATION, MANAGE YOUR EQUIPMENT YOUR WAY — WHENEVER, WHEREVER

-

Industries

Back

Industries

Our experts can provide tailored solutions that will enable you to perform at your very best within your industry

View More - About Us

- Career

- Training

- e-procurement

BUY PARTS

BUY PARTS

Contact Dealer

Contact Dealer